Engineered for efficiency and precision, our Solar Pile Machinery lineup includes specialized equipment for cutting, punching, bending, and processing steel piles used in ground-mounted solar installations. These machines are designed to streamline production, reduce labor, and ensure consistent quality in every pile—helping solar contractors meet tight timelines and demanding standards.

FMS has been a proud member of the National Precast Concrete Association (NPCA) since 2020.

Visit our News page for updates on the next annual NPCA exhibition

-

FMS Angle and Flat Bar Processing Line for Solar Structures

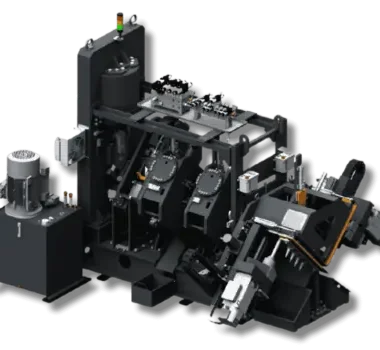

Designed for high-efficiency solar pile fabrication, the FMS Angle and Flat Bar Processing Line delivers automatic punching and shearing of W6 and W8 beam flanges. With CNC control, powerful tooling, and full profile automation, it’s the ideal solution for structural steel processing in solar applications.

-

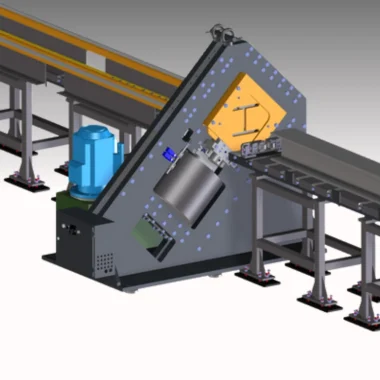

FMS Beam Processing Line for Solar Pile Systems

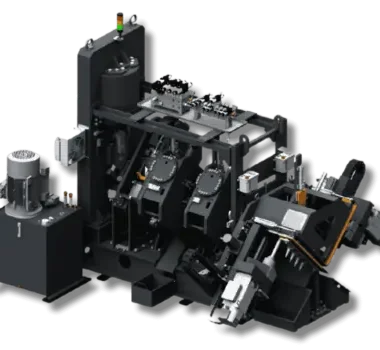

Built for speed, versatility, and zero-waste performance, the FMS Beam Processing Line automates the punching and shearing of angle and C-channel profiles used in solar pile and structural steel fabrication. CNC precision and advanced material handling make it a scalable solution for high-throughput environments.

-

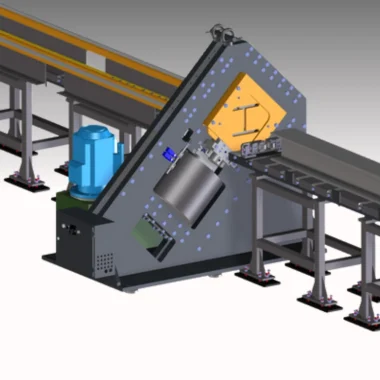

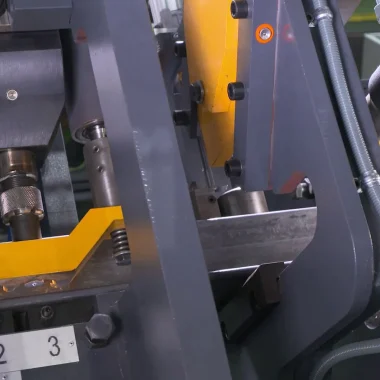

FMS Beam Shearing Machine for Solar Piles

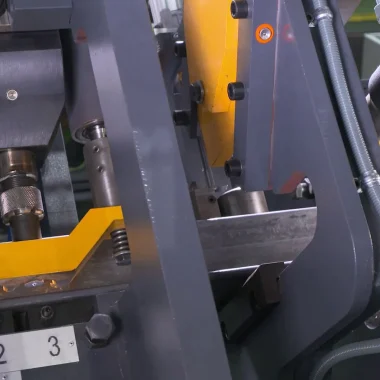

Engineered for clean, fast, and waste-free cuts, the FMS Beam Shearing Machine delivers high-speed manual shearing for W-beam profiles used in solar pile systems. With a 365-ton shear and precision roller handling, it’s a durable solution built for performance.

-

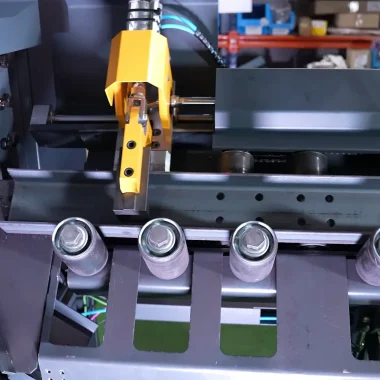

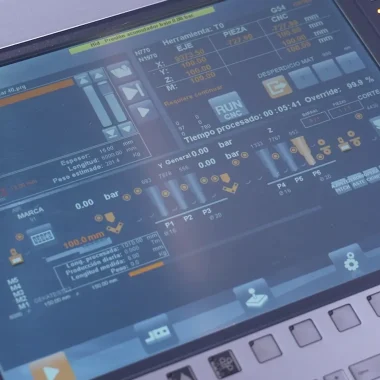

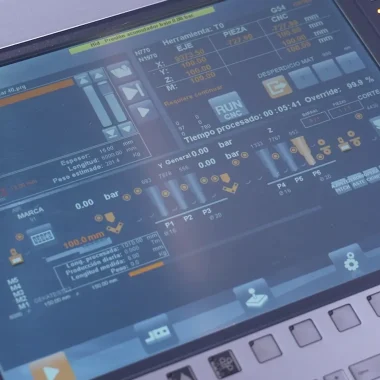

The FMS Drill & Saw Line, powered by the GK DSB series, combines high-speed CNC drilling with precision bandsaw cutting in a single, robust machine. Engineered for structural steel, C-channel, and profile processing, this fully integrated system delivers unmatched productivity, accuracy, and versatility for manufacturers of solar structures and heavy steel frameworks.

-

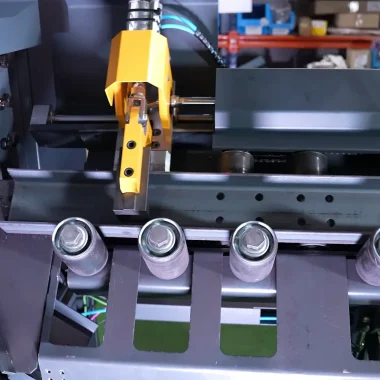

FMS Hydraulic Punching Machine for Solar Piles

Built for strength, flexibility, and high-output beam processing, the FMS Hydraulic Punching Machine delivers up to 440 tons of force and simultaneous punching on both flanges—perfect for W-beam profiles in solar tracker and pile foundations. Add the optional Shear Master module for a complete punch-and-shear line.

-

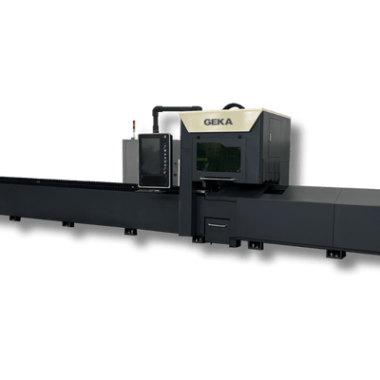

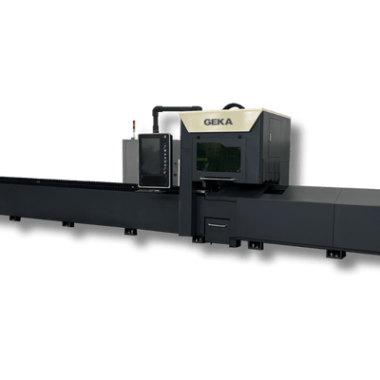

The FMS Laser Cutting Machine is a high-performance system designed to process pipes, beams, and structural profiles with exceptional speed and precision. With bevel-cutting capabilities and support for a wide range of shapes and sizes, it’s the ideal solution for solar tracker manufacturers and structural steel fabricators seeking flexible, clean, and accurate cutting in a single operation.